Enhanced TDS

Identification & Functionality

- Chemical Family

- Chemical Name

- Base Chemicals Functions

- CASE Ingredients Functions

- CAS No.

- 25013-15-4

- Technologies

- Product Families

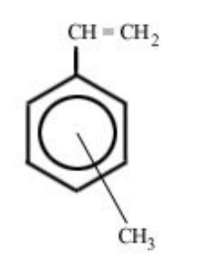

- Chemical Structure

Typical Isomer Distribution:

45% Para

55% Meta

Features & Benefits

- Base Chemicals Features

- CASE Ingredients Features

- Product Attributes

VT is a reactive monomer which readily polymerizes to form a high clarity, colorless polymer with excellent electrical and physical properties. Like styrene monomer, VT monomer can be polymerized by any of the conventional methods of initiation and in the presence of inert materials such as fillers, dyes, solvents, resins, rubbers and plasticizers. Copolymerization of VT monomer with other monomers such as acrylate, acrylonitrile, butadiene, divinylbenzene or methacrylate and maleic anhydride yields products with wide variations of physical properties.

Applications & Uses

- Markets

- Applications

- Base Chemicals End Uses

- Applications

- VT monomer is widely used in the coatings industry as a modifier for drying oils and oil modified alkyds. These monomer modified resins have good chemical resistance, fast drying, durability, excellent solution color and color retention properties. Another important advantage for VT modified oils and alkyds is their solubility in low cost solvents.

- VT monomer is used as a replacement for styrene monomer in unsaturated polyester resins (UPR) where high temperature cures combined with less shrinkage are desired. UPRs formulated with VT monomer exhibit a lower vapor pressure at any temperature and a higher flash point.

Properties

- Physical Form

- Physical Properties

Value Units Test Method / Conditions Refractive Index (n25D) 1.5395 - - Density (at 25°C) 0.893 g/cc - Surface Tension (at 25°C) 31.0 dynes-cm-¹ - Boiling Point (at 760mm Hg) 168.0 °C - Heat of Vaporization (at 25°C) 98.2 cal/g - Freezing Point -77.0 °C - Volume Concentration on Polymerization (at 25°C) 12.0 % - Specific Heat (at 25°C) 0.413 cal/g °C - Carbonyls (CHO) 10.0 ppm ASTM D-2119-82 Chlorides 5.0 ppm XRF Sulfur 25.0 ppm XRF Viscosity (at 25°C) 0.78 cps - Vapor Pressure (at 40°C) 4.0 mm.Hg - Vapor Pressure (at 80°C) 35.0 mm.Hg - Vapor Pressure (at 120°C) 176.0 mm.Hg - Vapor Pressure (at 180°C) 616.0 mm.Hg - Heat of Polymerization 15 - 17 Kcal mole-¹ - Copolymerization (Q Values) 1.06 - - Copolymerization (e Values) -0.78 - - - Typical Properties

Value Units Test Method / Conditions Molecular Weight 160.26 g/mol - - Chemical Analysis

Value Units Test Method / Conditions Minimum Assay 99.2 - 99.5 % Isomer Distribution (Para) 45.0 % GC Isomer Distribution (Meta) 55.0 % GC Polymer Negative ppm ASTM D-2121-84 Inhibitor TBC 12.0 ppm -

Regulatory & Compliance

- Certifications & Compliance

- Chemical Inventories

Storage & Handling

- Storage & Handling

Typical precautions in handling VT monomer include wearing protective clothing, the use of impermeable gloves and use in a well ventilated area. Do not store in direct sunlight. Maintain storage temperature below 75oF if extended storage is required. VT monomer contains the polymerization inhibitor tertiary butylcatechol (TBC) to reduce polymer formation during storage. For other product safety and toxicological information, please consult the Material Safety Data Sheets for VT monomer.